What is Just in Time Inventory and Benefits of JIT

Content

Since you don’t have stock sitting around, you need to order the correct amount every time. This requires a lot of planning and insight into your sales trends. If a product has issues or doesn’t sell well, you can easily shift your efforts to one that does. In a Kanban system, you’d attach a card to every component or raw unit. Once the component just in time inventory is used to complete a finished product, the card is removed and sent back up the production line. These cards are collected, then used to trigger a replenishment order—just for the number of components or amount of raw material you’ve used. It’s more expensive to make smaller, more frequent orders than bulk orders every so often.

- Here we compare Periodic and Perpetual inventory and let you know which one comes out on top.

- Ordering stock materials only when they are needed enables you to maintain a healthy and smooth cash flow.

- So, if a car assembly plant needs to install airbags, it does not keep a stock of airbags on its shelves but receives them as those cars come onto the assembly line.

- Vikki leverages her nonprofit experience to enhance the quality and accuracy of Dotdash’s content.

Avoiding implementing the wrong inventory system for your business can be just as important as implementing the correct one. Price Shocks.In JIT, prices for parts involved in the production process are assumed to remain constant. When there are price shocks, the company’s profit margin can be greatly affected. JIT has the added benefits of allowing you to maintain a flexible workforce. Risk of Running Out of Stock – With JIT manufacturing, you do not carry as much stock. This is because you base your stock off of demand forecasts, and if those are incorrect, then you will not have the correct amount of stock readily available for your consumers. This is one of the most common issues with manufacturing that utilize methodologies such as JIT and lean.

What Are the Strategies Used in Production Planning & Scheduling?

Whether you’re currently using a just-in-time strategy or are looking for a new solution to your inventory woes, you’ll learn everything you need to successfully implement JIT in this guide. Here is a closer look at these two types of inventory management.

Supply chain management should fit your business goals – EPS News

Supply chain management should fit your business goals.

Posted: Tue, 29 Nov 2022 17:37:30 GMT [source]

For example, if an operation has a work content of one hour, the Just-In-Time start date will be set to one hour before the operation’s need date. Waste Elimination/Reduction – A quicker turnaround of stock prevents goods that have become damaged or obsolete while sitting in storage, reducing waste.

The Advantages of Just-in-Time Inventory Systems

Parts data can be updated and accessed in real-time by users through the CMMS. Maybe you are considering alternatives to just-in-time management, like MRP or OPT. This allows them to develop great relationships with their customers while giving each order 100% care and attention.

So if your supplier charges extra for your order due to a recent natural disaster or national holiday, it’ll eat into your bottom line. Overall, inventory management is an excellent strategy for any business that sells physical goods.

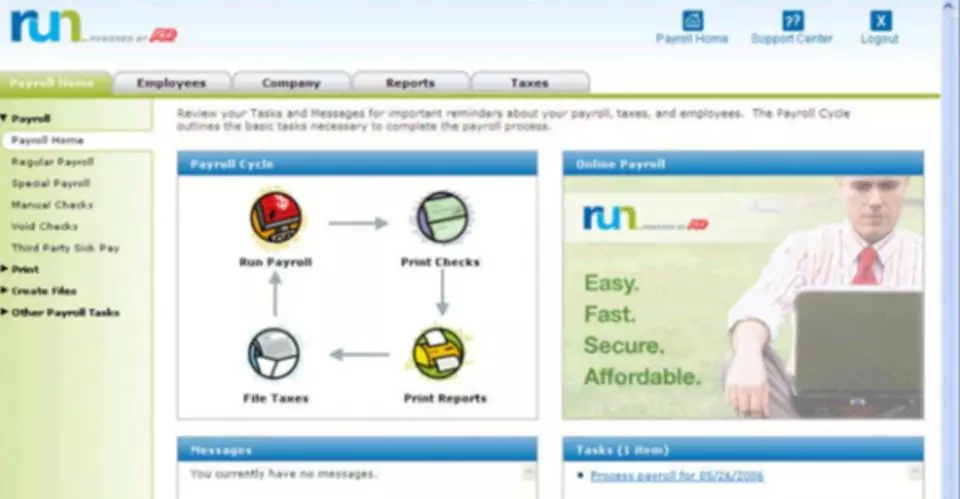

Implementing the JIT methodology

Walmart’s trucks literally “cross-dock” with supplier trucks and deliver goods straight to stores, just in time for employees to stock the shelves of depleted items. It may be one of the world’s most efficient just-in-time systems. But, a just-in-time inventory system is not exactly what it seems. There are many misconceptions about what JIT is, and a small business would do well to weigh the pros and cons before adopting this complex inventory system. The primary advantage of the just-in-time system is the reduction of inventory carrying costs. If implemented correctly, then it also improves operational efficiency and reduces waste.

A CMMS can help manage and monitor inventory even in uncertain times. Tracking inventory is vital to providing quality customer service. Here we compare Periodic and Perpetual inventory and let you know which one comes out on top. Katana gives thousands of manufacturers a live look at their business. Manage all the moving parts of your business and unite the apps and services you use in one visual platform.

Just-in-Time (JIT): A New Way to Do Inventory

A CMMS helps ensure that manufacturers have the right parts at the right cost just when they need them. When a customer places an order, you can be sure it will get fulfilled in time. We built Katana manufacturing software to bring lean manufacturing https://www.bookstime.com/ straight into the hands of manufacturers. It carries on the Kanban tradition – everything is accessible, nothing is wasted. They value transparency — customers make orders with full knowledge about the length of the production process.

- If a product goes on back order or a natural disaster strikes, you may experience disruptions in your supply chain.

- They built small factories that only kept the raw materials needed for existing orders.

- This approach has caught on since Toyota invented it because it can lower costs and increase profitability in a big way.

- The model is dependent on suppliers’ performance and timeliness, which are hard to ensure.

- JIT inventory management involves having fewer items moving on the shop floor at any given time.

JIT inventory management increases productivity by reducing the time and resources required for manufacturing. You can also implement product changes quickly as there is less raw material stock. Product damage is also reduced because of having lower inventory levels. Ordering inventory on an as-needed basis means that the company does not hold any safety stock, and it operates with continuously low inventory levels. This strategy helps companies lower their inventory carrying costs, increase efficiency, and decrease waste.

Advantages and Disadvantages

JIT employees are often certified to work on different tasks within the production process. This gives them more work to do and cuts costs to the business like the cost of physical counts of inventory. Identify manufacturing vendors with slow or inconsistent production times and third-party logistics companies with unreliable delivery times. Replace them with more reliable partners to smooth out your supply chain so you can get your JIT shipments faster.